Real-Time Monitoring for Smarter Industrial Operations

Field instruments are essential devices used in industrial plants and factories to measure, monitor, and control key operational parameters such as pressure, temperature, flow, level, and chemical composition. Installed directly at the operational site, these instruments provide real-time data that is transmitted to central control systems like DCS (Distributed Control System) or PLC (Programmable Logic Controller) to ensure smooth, safe, and efficient plant performance.

These instruments serve as the frontline eyes and ears of automation systems, helping engineers and operators maintain process accuracy, detect faults early, and optimize energy use.

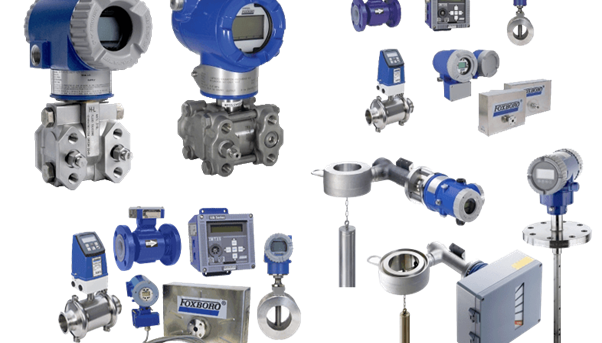

Types of Field Instruments

Measurement Instruments

Used for measuring physical parameters such as temperature, pressure, flow rate, and level. Examples include thermocouples, pressure transmitters, flow meters, and level sensors.Control Instruments

Devices that receive input from measurement tools and automatically adjust system behavior. Examples include valve actuators, PID controllers, and positioners that ensure precise control of processes.Analytical Instruments

These measure the chemical composition of substances in a process, ensuring product quality and compliance. Common types include gas analyzers, pH meters, and conductivity sensors.Safety Instruments

Specifically designed to prevent hazardous conditions by monitoring critical limits and initiating shutdown or alarms. Examples include smoke detectors, pressure relief devices, and emergency shutdown systems (ESDs).

At PAEPL, we offer a comprehensive range of field instruments designed to enhance automation, improve safety, and support high-efficiency operations across industries. Whether you’re managing a chemical plant, a power station, or a food processing unit — our solutions are engineered for reliability and performance.

Field instruments that bring precision, safety, and intelligence to your industrial environment.