Air Handling Units

An Air Handling Unit (AHU) is a key component of an HVAC (Heating, Ventilation, and Air Conditioning) system. Its primary role is to regulate and circulate air within a building to ensure a comfortable indoor environment.

The AHU works by drawing in both outdoor and indoor air, filtering out dust, pollutants, and particles, and then adjusting the air’s temperature and humidity as needed. Once conditioned, the air is distributed through a network of ducts to different areas of the building, delivering clean, fresh, and climate-controlled air to occupants.

Whether installed in commercial complexes, hospitals, offices, or large residential buildings, AHUs play a vital role in maintaining air quality, comfort, and energy efficiency.

Incase of Queries, Feel Free To Reach Us At 042-35153686

What is an AHU and What Does It Stand For?

AHU stands for Air Handling Unit. It is a vital component of an HVAC (Heating, Ventilation, and Air Conditioning) system, responsible for regulating, conditioning, and circulating air throughout a building.

An AHU draws in outdoor and return indoor air, filters out impurities such as dust and allergens, conditions the air by adjusting its temperature and humidity, and then delivers clean, comfortable air through ducts to different rooms or zones in a building.

AHUs are commonly found in commercial buildings, hospitals, shopping malls, industrial facilities, and large residential complexes, ensuring healthy indoor air quality and thermal comfort.

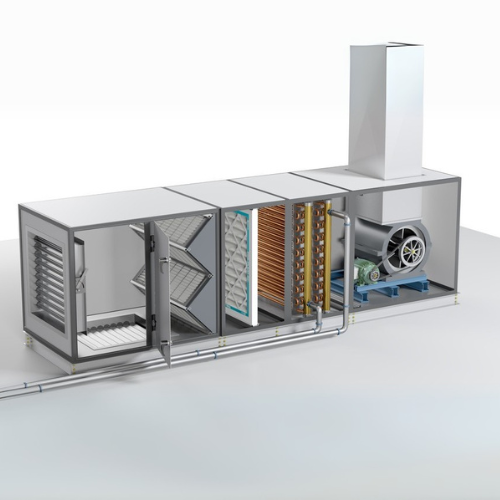

What Are the Main Components of an AHU, and How Does It Work?

The Air Handling Unit is a sophisticated assembly of several components that work together to process and distribute air. Below is a breakdown of its key parts and how the AHU system operates:

1. Filtration System

Function: Removes airborne particles such as dust, pollen, and pollutants.

How it works:

As air enters the AHU—either from outside or returned from within the building—it first passes through air filters. These can range from simple pre-filters to HEPA or carbon filters depending on indoor air quality requirements. Filtration is the first and most crucial step in ensuring clean, breathable air.

2. Cooling Coils and Heating Elements

Function: Regulates the air temperature to match comfort requirements.

How it works:

After filtration, air flows over either cooling coils (connected to chilled water or refrigerant systems) or heating elements (electric or hot water coils).

In summer, cooling coils absorb heat from the air, reducing temperature.

In winter, heating elements warm the air before it’s distributed.

This stage ensures the air is conditioned to a set temperature before being sent through the ductwork.

3. Control Dampers

Function: Direct and regulate the airflow.

How it works:

Dampers are mechanical devices that adjust the volume of air flowing to different zones of a building. They may be automatically or manually controlled and help maintain balanced temperature and airflow in various areas. Dampers can also help mix fresh air and return air to maintain proper indoor air quality.

4. Fans (Blowers)

Function: Circulates air through the AHU and into supply ducts.

How it works:

Supply fans push the conditioned air through the duct system to designated rooms, while return fans may draw stale air back to the AHU. The fan’s speed and capacity determine how efficiently air is circulated across the system, ensuring uniform air distribution.

5. Control System

Function: Monitors and manages the AHU’s operations.

How it works:

The AHU is equipped with sensors, actuators, and a programmable controller that manage the temperature, humidity, pressure, and fan speed. These systems allow for real-time monitoring and automatic adjustment to maintain optimal performance and energy efficiency.

Summary: How Does an AHU Work?

Air intake – outside or recirculated air enters the AHU.

Filtration – removes dust, allergens, and pollutants.

Temperature adjustment – air is cooled or heated via coils or heaters.

Airflow control – dampers regulate where air goes.

Air circulation – fans push the conditioned air into the ductwork.

Automation – control systems continuously adjust parameters for efficiency.