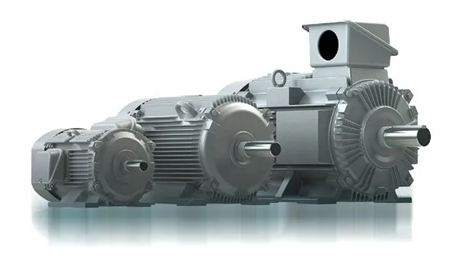

Types of Industrial Motors

. AC Motors (Alternating Current)

Most widely used in industrial environments due to reliability and efficiency.

Squirrel Cage Induction Motors

- Most common type.

- Simple, rugged, low maintenance.

- Used in fans, pumps, conveyors, etc.

Wound Rotor Induction Motors

- Offers better speed control and torque.

- Used in hoists, cranes, elevators.

Synchronous Motors

- Maintains constant speed regardless of load.

- Used in precision machinery, high-power applications.

. DC Motors (Direct Current)

Used where precise speed control or high starting torque is needed.

. Brushed DC Motors

- Simple, inexpensive, but require maintenance.

- Used in portable tools, small machinery.

. Brushless DC Motors (BLDC)

- High efficiency, low maintenance.

- Used in robotics, packaging machines, automation systems.

. Servo Motors

- Provide precise motion control and positioning.

- Widely used in robotics, CNC machines, and automated manufacturing.

Stepper Motors

- Move in discrete steps.

- Great for low-speed, high-precision

- Found in 3D printers, labeling machines, and camera systems.

Special Purpose Motors

- Explosion-proof motors: For hazardous environments (oil & gas, chemicals).

- Brake motors: Integrated braking system for rapid stopping.

- Vibration motors: For hoppers, screens, and compacting machines.

Control Methods

- DOL (Direct On Line) – simple on/off switch

- Star-Delta Starter – reduced starting current

- VFD (Variable Frequency Drive) – adjust motor speed dynamically

- Soft Starters – smooth acceleration without spikes

Applications

- Pumps and compressors

- Fans and blowers

- Conveyors and material handling

- Machine tools

- HVAC systems

- Mixers and agitators